Silicone rubber sleeve

Part Type: Molding/Injection

Shape: as drawing such as 2D,3D or sample

Material Composition: EPDM

Aging resistance: 120℃; Low temp resistance: -40℃

Vacuum Collapse resistance

Ozone resistance

Meet SPEC.: ASTM D2000,SAE J200

Contact Us:sales2@fuste.com.cn

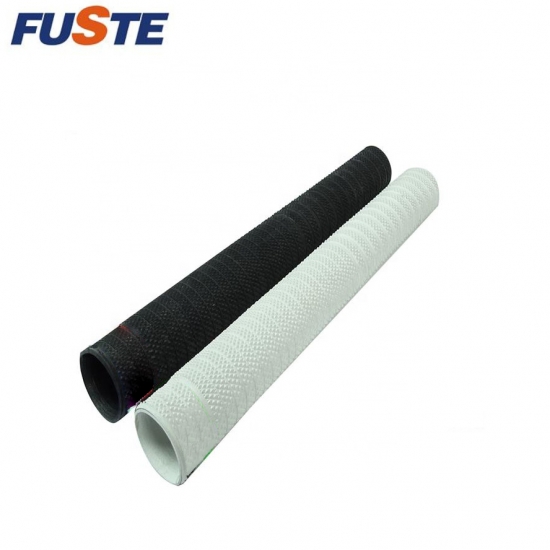

Silicone Rubber sleeve , also known as Silicon Handle Grips, Silicone Handle Grip Cover, which are made from elastomeric silicone rubber materials as a cover for metal or plastic handles (some is Metal & plastic + silicone rubber overmolding handle grip), which are usually used as elastomeric surface sleeve for pot & pan handle, pull handle, twist handle and wide-range motion handles, which is made by compression molding tooling, silicon injection mould and extrusion tooling with horizontals stripe.

Common Silicone Rubber Handle Grips & Cover: bicycle & motorcycle handle sleeve, gulf grip sleeve, hammer handle sleeve, baseball bat sleeve, tennis racket sleeve, croquet mallets grip sleeve, handbrake handle sleeve, pot & pan handle sleeve.

Rubber Handle Grips Features: Anti-Slip designs, Heatproof, and Electric Insulation etc.

Silicone Rubber Sleeve Surface or Process:

1. Texture surface: in aim to increase friction against the hand ( anti-slip effects )

2. Silk Screen Printing: First, making the printing tool, and mix the ink, then put silicone parts on the positioning tool, and start printing, in order to make the printing result thicker & more beautiful, need printing on the surface twice.

3. Roll Printing: Notes: The difference between Roll Printing and Transfer Printing for Silicone Bottle Sleeves

Printing Thickness: Roll printing is more thick, and logo & text surface better than transfer printing's

Printing Cost: Transfer Printing is more cheap

Printing Technology: Transfer Printing is flexible

Surface treatment: Matte Smooth coating can make the silicone sleeve have a better tactility.

4. Embossed Logo: Generally, most of our customers will choose embossed production process for Logo, because printing logo needs extra cost and debossed logo is easy to get dirty and not easy to clean.

5. Matte Smooth Coating: for a good touch feeling, anti-dust effects, and protect silk screen printing Logo or patterns, and reduce silicone rubber handle grips parting line or rubber flashing, to make it more beautiful.

online service

online service